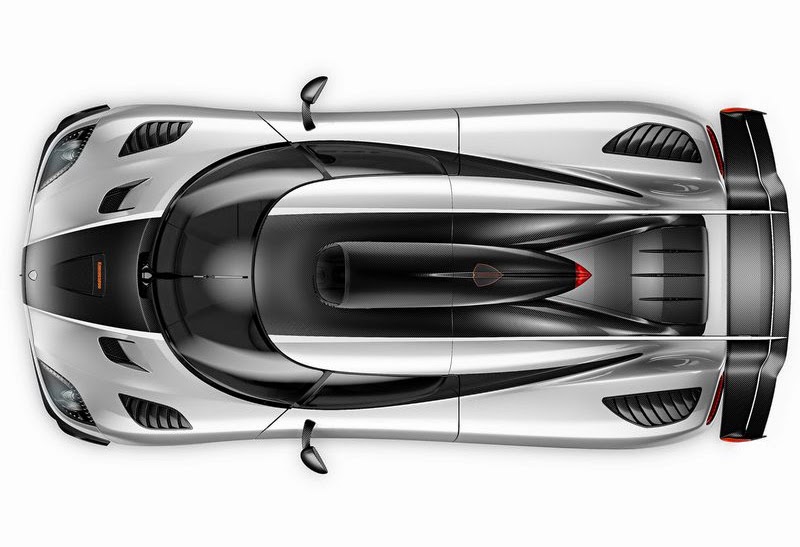

THE DESIGN

The Agera is designed with the minimalistic "less is

more" philosophy in mind. This philosophy means that the shape of the

car has to be purely functional with no added features except those

purely needed to meet regulation, added safety, ergonomics, practicality

and aerodynamics. We believe that if this philosophy is followed, the

car will also be beautiful as it is purely purposeful. A good analogy is

the evolution of a dolphin that has had to meet similar criteria in order to reach their present configuration through the evolution of nature.

The

Agera is proportionate, compact and muscular. Its timeless, efficient

and distinctive shape is truly a testament to time. The original shape

and concept of the Koenigsegg CC, created 15 years ago, is still valid,

fresh and highly competitive today. The Agera manage to stay true to the

original philosophy, shape and size of the original CC. At the same

time, it looks, feels and performs like something belonging to the

future.

THE ENGINE

Koenigsegg differs from other low volume

hypercar manufacturers by the fact that Koenigsegg develops and produces

its own engine in-house. This is, by most observers and competitors,

deemed as more or less impossible or way too expensive to even consider.

However,

year after year Koenigsegg has proved them wrong. Not only are the

engines developed in-house, they also have class leading characteristics

in many important areas. To mention a few: Lightest and most compact

hypercar engine in the world, weighing only 197 kg complete with

flywheel, clutch, dry sump system, Inconel exhaust manifold with turbo.

The low engine weight is quite astonishing, as the Agera engine also has

class leading power and torque characteristics. To give an example, the

Koenigsegg 5 litre V8 bi-turbo engine develops more than 900 hp on 95

octane regular fuel, and more than 1100 hp on E85 bio fuel. The Agera

produces over 1000 Nm of torque from 2500 rpm and in the Koenigsegg

Agera R format the engine has a peak torque of 1200 Nm over a 3300 rpm

rev range, showing great flexibility.

These are extraordinary

numbers considering the size and reliability of the engine without

forsaking drivability or flexibility. This is truly downsizing, without

drawbacks. These characteristics make it one of the most flexible and

easy to use hypercar engines in the world.

The Agera engine has a

BMEP of 28 bar running on 95 octane fuel and the E85 Bio fuel

Koenigsegg Agera R engines has an astonishing BMEP of 30 bar. These

numbers show how extreme the Koenigsegg engines are compared to any

other production engine in the world. The reason why Koenigsegg can

obtain such BMEP figures is due to some proprietary and critical

factors:

- A unique shape of the combustion chambers, improving the resistance against detonation.

- High cylinder head clamp load, enabled by a specially designed

engine block. This has proven to give a zero failure rate to combustion

overpressure, even considering the extreme cylinder pressures.

- A unique engine block design, where the cylinder sleeves are used to further stiffen the aluminium block.

- A connecting rod design reducing TDC dwell time and therefore enabling higher mean pressures without detonation.

- Exhaust manifold and intake plenum trumpets designed to ensure absence of RPM peak resonance and back pressure.

- An efficient ejector pump system reducing the crankcase pressure and aerodynamic losses.

The Koenigsegg engines also meet all the required emission standards

in the world. This is nothing short of astounding, given their size and

power output.

Koenigsegg has its own engine lab, with simulation

programs, rapid prototyping machines, engine and chassis dynamometers,

and a 1.7 km test track adjacent the factory enabling Koenigsegg to take

the cars to 0-320-0 km/h at any time. Furthermore, a 25 minute drive

away from the Koenigsegg Factory there is Knutstorp Racetrack, which is

described by many as a miniature Nordschleife. Here Koenigsegg can put

the engine and car through serious testing and make sure they work in

perfect harmony. This gives Koenigsegg unique possibilities to develop

technologies normally exclusive to much larger companies.

No

other production engine in the world, regardless of car type, has the

same amount of power potential compared to its EU cycle average CO2

emission(310g of CO2) or cycle fuel consumption( 14,7 litre per 100 km /

16MPG). However, what makes Koenigsegg most proud is how drivable,

smooth, responsive, torquey and reliable the engines are - especially

given their extreme performance.

The Agera engine complies with

the most stringent environmental regulations in the world, EU5 and LEV2,

and delivers a significant power increase compared to previous

Koenigsegg engines.

Fuel consumption, and thus CO2 emissions, has

been lowered. This is an astonishing feat for a 900+ hp hypercar. Turbo

response is of vital importance when it comes to driving pleasure and

the possibility to control massive amounts of power. Therefore

Koenigsegg has joined forces with Borg Warner and adapted to the latest

technology when it comes to turbine materials. The Koenigsegg Agera R

turbines are made from a material called Gamma-Ti which is an inter

metallic compound comprised of aluminium and titanium. This new material

drastically reduces the inertia of the turbine wheel and axle and

therefore gives improved response. Furthermore Koenigsegg has coupled

this latest generation turbo technology with patent pending and

proprietary response/back pressure reduction system, invented by

Christian von Koenigsegg to really give the Agera engine a competitive

edge when combining maximum power while complying with the strictest

emission regulations in the world.

Furthermore the large air to air

intercooler on the left side of the engine sucks enormous amounts of

fresh air, eliminating the need for water in the intercooling system,

thereby saving weight and avoiding heat soak issues, during extended

performance driving.

Following the Koenigsegg tradition the engine

has a dry sump lubrication in order to lower the engine as far as

possible in the chassis and have full control of the crankcase oil even

given the massive g-forces involved.

The large 80-litre tank

ensures long driving range, due to the relatively low average

consumption. The Agera follows the previous generation Koenigsegg and

has its fuel tank well protected, built-in centrally into the carbon

fibre monocoque chassis. Since the fuel is centrally placed in the car,

the weight distribution does not change regardless if the tank is full

or empty. Thanks to the safe fuel tank position, the challenging US high-speed rear impact test, was passed at first trial.

The

Koenigsegg Agera R has four intelligent bio fuel grade return-less fuel

pumps to deliver the correct amount of fuel at any given time. This

reduces the energy needed to operate the fuel pumps and eliminates the

waste of excessive fuel transport.

The inconel/titanium patent

pending exhaust system is key in order for the Agera to achieve its

remarkable emission and power levels. The exhaust system uses a

completely new principle created by Christian von Koenigsegg. The new

technology drastically reduces back pressure and gives earlier catalytic

light off than any other turbo exhaust system. At the same time the

acoustics of the exhaust has been examined carefully in order to

maintain the typical Koenigsegg thunderous growl.

THE TRANSMISSION

The

newly developed 7 speed gearbox for the Agera features a world's first

dual clutch system for a single input shaft gearbox. In order to keep

the gearbox light, compact strong and reliable, Koenigsegg together with

Cima chose to develop a new gearbox type that enables the use of a

combination of a dry and wet clutch system, in order to get class

leading shift times. First there is the normal twin disc dry clutch that

operates in a traditional fashion. Then there is a hydraulically

operated wet clutch-brake inside the gearbox that is engaged during each

up shift in order to slow down the input shaft, simultaneously as the

gears are changed and prior to the normal synchronisation. This cuts the

synchronisation time by two thirds, as the gear is presynchronized. The

result is a very sporty, smooth and extremely fast shift. Compared to a

traditional DCT system, this gearbox is lighter, smaller, has less

moving parts and gives a more distinct shift feel, with almost no

interruption to the acceleration. Furthermore, the electro hydraulic

shift mechanism actuates the shift forks directly with no intermediate

mechanical parts. This brings down the inertia of the shift mechanism

and any potential slack is minimized since the shortest possible path of

engagement is achieved.

The entire transmission weighs only 81

kg, which is by far the lightest 7 speed Hypercar transmission in the

world. The transmission can also be set in full auto mode.

The

small size and very low weight, considering the longitudinal 7 speed

layout, made it possible to maintain the shortest in class rear

overhang, and thereby excellent central mass position and neutral

behaviour in extreme conditions.

Koenigsegg E-Diff

The

Koenigsegg Electronic Differential (E-Diff) is lighter and faster,

compared to traditional E-Diff solutions. The difference lies in the

fact that Koenigsegg has retained a limited slip differential with

plates and ramps with a built-in amount of analogue limited slip

functionality. This means that the active hydraulic element can be

smaller, more compact and therefore faster and lighter compared to

traditional E-Diff solutions. The analogue part of the functionality

also has zero processing time as it reacts directly. The analogue system

is supplemented by a digital active system.

The way Koenigsegg

has obtained one of the lightest and fastest E-Diff solution on the

market. Furthermore the Koenigsegg developed algorithms that control the

E-Diff, takes input from; throttle angle, g-force, steering wheel

angle, yaw angle, car speed, engine rpm, selected gear, plus weather

condition.

The way all this data is analysed and how the car reacts

to this data also makes the Koenigsegg E-Diff unique and that makes the

Agera very safe on the limit and improves performance and feel.

The

Koenigsegg E-diff works in harmony with the new traction control system

that is the fastest reacting in the industry, with auto adapt

functionality to different road conditions and driving styles as well as

several manual settings.

THE CHASSIS

The Agera´s unique

carbon fibre monocoque chassis is designed to achieve its maximum

stiffness without a roof, as the roof is detachable and stow-able in the

front of the car. This in itself is an unusual feature for such a

compact Hypercar.

The Koenigsegg carbon monocoque chassis has an

astonishing stiffness of 65.000 Nm/deg and only weighs 70 kg including

the integrated fuel tanks.

The result of constant weight saving

exercises is a dry weight of only 1330 kg making the Agera the lightest

fully homologated Hypercar presently in production.

THE SUSPENSION

The

suspension geometry of the Agera was designed to further enhance the

award winning behaviour of the CCX. The Agera track is wider at the

front compared to the rear of the car, compensating for the narrower

front tires and giving the car a square stance of 2 meters in both the

front and the rear.

In typical Koenigsegg tradition, the Agera

has the longest wishbones of all hypercars presently in production. Long

wishbones have several advantages - for example: less track width

deviation during wheel movement or cornering and improved geometry over a

longer wheel stroke. This is one of the reason why F1 cars have very

long wishbones. The wishbones are produced from seamless aeronautical

chrome-molybdenum tubing, in order to minimise weight in combination

with maximum strength and stiffness.

The extremely strong and

light uprights are machined from 7075-T6 aeronautical grade aluminium,

and contains 240 mm SKF dual angle contact bearings, normally only found

on Lemans prototype cars. The very large bearings contribute to the

overall stiffness of the wheel assembly and therefore give better

control, handling and comfort. The uprights have large 4.5" diameter

carbon fibre cooling ducts for the brake discs in order to maximise

brake cooling.

Brakes

The Agera is equipped with the

absolutely latest ABS technology and is based upon, a very lightweight

and performance oriented, racing ABS system. The system makes it

possible for the ABS function to react to differently depending on

performance mode. Furthermore the ABS braking system operates on massive

392×36 mm and 380×34 mm ventilated and drilled ceramic discs, for

unparalleled braking performance and zero fade regardless of track or

road condition.

RTD (Rear Triplex Damper) Suspension

Christian

von Koenigsegg has invented and pioneered a new type of rear suspension

system for a road car. The Agera has a shock absorber and spring

connecting the right and left rear wheel. This system gives unique

benefits as the two rear wheels can influence one another when desired.

There

are multiple benefits of this system. For example, the extra spring and

damper works in series with the normal spring and dampers allowing

their spring and damping rates to be lowered. This results in increased

comfort and better handling on rough and wet surfaces without

compromising dry track handling.

Furthermore the RTD system has

an anti-squat effect. Traditional anti-squat systems are designed into

the geometry of the suspension. These systems do not add any components

or weight. However they compromise the geometry of the suspension for

other aspects of handling than anti-squat.

By adding the RTD system,

Koenigsegg can maintain true suspension geometries for handling, but

still have the anti-squat feature and harvest other new found benefits.

As the RTD system compliments the normal dampers and springs, these can

be made lighter. Hence, the added benefit does not significantly affect

the overall system weight.

DEDICATED MICHELIN TIRES

Koenigsegg

continued its long standing partnership with Michelin in the tire

development for the Agera. Hence the Agera features specially developed,

latest generation Michelin Super sport tires.

Due to the tires,

advanced suspension and aerodynamics, the Agera achieves lateral

accelerations up to 1.6 g in dry conditions with improved handling in

wet.

The new tires were developed for the Agera through testing at the Michelin Ladoux test centre in France.

The

tires fitted to the Agera are rated for speeds over 420 km/h making it

the highest top speed rated tire in the world, whilst offering cup tire

levels of grip and outstanding wet performance , all in one package.

Koenigsegg are very proud of being a selected development partner of Michelin.

VGR - Vortex Generating Rim spokes

The

Koenigsegg VGR wheels are not only for looks. They are real air

turbines, increasing the down force of the car by measurable amounts and

improve brake cooling. All four wheels are individual so that turbine

blades always face the correct direction for extraction. Given that the

offset and width is different front to rear, all four wheels have their

unique design. The VGR wheels are forged and then fully machined to the

final shape. Due to the forging and machining process all excess

material has been removed minimising weight, whilst displaying

outstanding levels of stiffness.

THE AERODYNAMICS

The

Aerodynamics of the Agera has been honed and perfected over many years

in CFD and wind tunnel in order ensure best possible outcome. Even with

the massive dynamic rear wing, the drag of the Agera is only Cd 0.33, in

high speed mode and Cd 0.37 in track mode. Even though the Agera is a

full 2 meters wide, it only has a frontal area of 1.87 m2. This results

in a Cd*A value of only 0.62 and thus a theoretical top speed of around

440 km/h (Agera R), given the gear ratio and power available. All Agera

models are limited to 375 km/h in standard mode, but can be unlocked by

Koenigsegg for shorter periods of time, if all necessary conditions are

met, such as road condition, tire wear, service level of car etc. The

car is set in full speed mode by unlocking the top speed mode in the

Infotainment system.

The two large side air intakes greatly add

to the Agera´s high speed stability as they ensure that the pressure

point of the car is behind the mass centre of the car. This makes the

car more directionally stable with increasing speed. This is a crucial

safety feature when it comes to driving at extreme speeds. Great care

has been taken that the car also is stable under high speed braking. The

front splitter and rear diffuser has been designed and optimized with

this in mind.

For maximum performance and safety it is important

that the down force stays as constant as possible even in yaw

situations. Therefore the rear diffuser was developed and evaluated

specifically to give substantial down force even at wide yaw angles.

Dynamic rear wing

Hypercars

of today generate massive amounts of down force in low to medium speed

and less down force in very high speed, in order not to overload the

tires and not to create too much drag. Most hypercars therefore have

heavy hydraulically operated wings and flaps to cater for this need.

Koenigsegg

however, following the "less is more" philosophy, has designed a

dynamic system to that take care of the above described needs. The most

visual and obvious part of this system is the new dynamic rear wing. The

wing changes its angle of attack, not with the help of hydraulics, but

with the pressure of the wind. It is therefore dynamically controlled by

the speed or wind resistance at any given moment in time and thus

actually compensates for headwind or tailwind at the same given speed.

This is an intelligent way of dealing with adaptive aerodynamics, as the

system becomes lighter, less complex and more intuitive compared to

heavy and complex hydraulics systems. Koenigsegg had to work heavily

with CFD in order to create the dynamically controlled adaptive

aerodynamics of the Agera.

Furthermore, an interesting

multifunction feature of the adaptive wing is that the pylons for the

wing also act as air extrusion channels. The air channels goes from the

engine bay to the back of the pylons, thereby creating an air passage.

This causes a venturi effect, from the air rushing past the pylon,

evacuating hot engine bay gases, reducing pressure in the engine bay and

increasing the flow of cooling air through the side radiators. This

also means that the pressure under the car is reduced and giving more

low drag down force.

THE INTERIOR

The interior of the Agera is

like no other car. No other materials than those deemed worthy by

Koenigsegg are allowed in the interior. This means that what you get to

touch and see inside the Agera is only aluminium, carbon fibre, precious

metals, alcantara and aniline leather. All switch gear is highly

bespoke and features wonderfully unique solutions, as for example the

Koenigsegg Ghost light, that make solid aluminium buttons gleam with LED

powered symbols appearing out of nowhere. A world first in the car

industry. The illumination shines through the billet aluminium buttons

and surfaces by way of almost invisible micro holes, creating excellent

visibility of the symbols as well as a very clean and stylish

appearance, framed by an all-new carbon fibre centre console and tunnel

assembly.

The new super light full carbon airbag steering wheel

incorporates many vital functions directly in front of the driver.

Similarly to the CCX, the shifting paddles are mounted directly on the

steering wheel to enable shifting without taking your hands off the

steering wheel during hard cornering.

The central high-definition

touch screen infotainment system controls the audio functions,

satellite navigation, Bluetooth phone and secondary functions such as

performance meters and car telemetrical data.

The very comfortable

and optionally heated carbon seats are great for long journeys but also

give excellent lateral support when needed.

The Interior of the

Agera is truly minimalistic and efficient in the purest Swedish sense.

Nothing in the interior is there only to add visual drama; instead

everything is there for a functional purpose. According to Koenigsegg,

this is the essence of beauty, as it follows a less is more philosophy

that embodies every engineering aspect of the Agera.

CI - Configurable Instruments

The

CI is specifically developed for the Agera by Koenigsegg. It features a

unique and configurable interface that can be adapted to driver

specific demands. As it is connected to the cars CAN bus system it

freely communicates with the infotainment screen and all other functions

in the car.

By pushing the left stalk button, different priority

graphics can be chosen, depending on need. For example in track driving

mode, there is a focus on; RPM, pressures, temperatures, lap times, and

g-forces. Compared to GT mode, where: car speed, auto shift, satnav,

power, music etc is prioritized.

THE LUGGAGE SPACE

The luggage

space is something Koenigsegg is very proud of. It is the largest

luggage compartment in the hypercar world, with a space of over 120

litres. It is so well shaped that it actually can fit the one piece

Agera roof/hardtop, meaning the driver can choose to go open or closed

at any given time during a longer trip. Given the fact that Koenigsegg

has engineered the roof to fit the car, it is actually also possible fit

a set of golf clubs. This is unheard of in the hypercar world. Given

the high comfort level and the large luggage space, the Agera can truly

been seen as one of the first GT hypercars.

Custom Carbon fibre Thule Lightning Roof Box

At

the 2011 Geneva Motor show, Koenigsegg presents the Koenigsegg winter

package - the first lifestyle packages offered from Koenigsegg. The main

element of this package is the exceptional Lightning Roof Box System.

The

Lightning Roof Box is developed together with the Swedish rack and roof

box manufacturer Thule. The high performance lightweight box is made

completely from carbon fibre and has been through several iterations of

CFD simulation to ensure it is safe up to 300 km/h, making it the

fastest roof box in the world.

The roof box, which has an

incorporated roof panel, replaces the normal roof in under 10 minutes.

The standard roof is then stored in the luggage compartment in the front

of the car, so that when the driver arrives to his destination, the

roof box can be quickly removed and the normal roof can be put in place

for a more elegant look.

The Lightning roof box truly enables the

driver to use the Agera for longer trips with massive luggage. This

gives a whole new spectrum of hypercar utilization.

The winter

package also includes Michelin snow tires on forged Koenigsegg wheels

and custom designed Koenigsegg skis from the Swedish high end ski

manufacturer, Extrem.

Part of the winter package is also a Swedish

winter resort experience in Åre - Sweden's most popular skiing resort

and the place of manufacture of the Koenigsegg skis.

During the stay

in Åre, the Koenigsegg customers will be fitted for their skis and they

can witness first hand when they are being hand made in "Åres

skidfabrik", a state of the art ski production plant.

While their

skis are being made, they will be checked into the delightful

Copperhill Mountain Lodge that is towering snow-capped forests and

sparkling frozen lakes.

The following day the skis are ready for use

and Åre´s many and varied ski slopes are available for test runs, in

direct access from the Copperhill Mountain Lodge.

Together with the Golf club options this marks the start of the Koenigsegg extended lifestyle program for Koenigsegg cars.

We

would also like to thank Full Tilt, Houdini Sportswear, Sweet

Protection, Sport Lodge'n Trysil and Moods of Norway, for assisting us

in creating the winter experience at the Geneva motorshow.

THE ELECTRONICS

Not

only does Koenigsegg develop their own engines, but also many of the

electronic control units, CAN protocols, and management strategies are

developed in-house. If you would look closely at many of the circuit

boards in the car, inside the control units, you will find the name

Koenigsegg in scripted directly on the circuit boards.

Of course

there is no self fulfilling need to develop so many critical items

in-house, unless it gives the car a competitive edge doing so. This is

actually the main reason for Koenigsegg doing it. This, for example,

gave Koenigsegg the possibility to pioneer the CCXR and Agera R - the

two first environmentally conscious hypercars in the world.

An

example of this development is In the Semiconductor Electric Control

Central. The ECC controls most of the electronic functions in the car.

Most physical fuses or relays have been replaced by software controlled

semiconductors which are configurable in function and enable monitoring

all power and threshold values. The ECC communicates via CAN with the

infotainment system in order to display necessary information to the

driver. For example if a door is open, a lamp is broken, or not all roof

locks are tight in place, information will appear on the instruments as

all electrical functions are controlled and monitored by the ECC.

Intelligent Lifepo4 Battery - ILB

The

Agera is the first combustion engine powered production car in the

world, with an intelligent Lithium Iron battery as standard equipment.

First of all, this battery type saves significant weight and is more

compact compared to traditional led acid batteries. Secondly lithium

iron cells cannot reach thermal runway, unlike Li-ion batteries, which

makes them very safe for automotive use.

Koenigsegg has therefore

implemented a minimum current protection mode, to make the above issues

something of the past. The new ILB therefore has an intelligent circuit

built into it, so if the car is left on or standing for a long time, the

battery shuts down when the voltage drops below a certain threshold.

The shut down does not occur sooner than a traditional battery would

have been left depleted and useless, so it does not take away any

expected battery capacity. Then, if any essential buttons or a door knob

is touched, the battery kicks back into life for 5 minutes and has

enough power to operate all the functionalities in the car and start the

engine and thereby giving charge back to the battery.

TECHNICAL DATA

- Koenigsegg developed, aluminium/carbon fibre, dry sump, 32 valve, Twin Turbo, V8 engine

- Torque: 1100 - 1200Nm - depending on version and fuel

- Displacement: 5.035 L. Bore: 90.7mm. Stroke: 95.25 mm. Compression ratio: 9.0:1. Max rpm: 7250

- Power: 940-1115hp - depending on version and fuel

- 7-speed, dual clutch, single input shaft, AMT Transmission with E-diff.

- Frontal Area: 1.873 m2

- CD 0.30 (no rear wing) - 0.33 (fixed normal Agera rear wing) - 0.33 to 0.37(adaptable wing)

- Luggage space: 120 litres

- Dry weight: 1330 kg

- Curb weight 1418 kg (all fluids plus 50% fuel)

- Maximum laden weight: 1600 kg(full tank, two passengers, full luggage)

- Length: 4296 mm

- Width: 1998 mm

- Height: 1120 mm

- Wheelbase: 2662 mm

- Front Track: 1700 mm

- Rear Track: 1650 mm

- Front overhang: 885mm

- Rear overhang: 752mm